Show table of content Hide table of content

For years, conventional wisdom suggested LCD screens were the safer long-term investment compared to their OLED counterparts. The narrative painted OLED as visually stunning but vulnerable, while LCD represented reliability and longevity. However, a comprehensive investigation spanning 18,000 hours of continuous testing has completely overturned this assumption. The data reveals an unexpected truth : OLED displays degrade gradually, whereas LCD panels experience catastrophic mechanical failures. This breakthrough study challenges everything consumers believed about display technology durability.

The massive testing protocol that changed everything

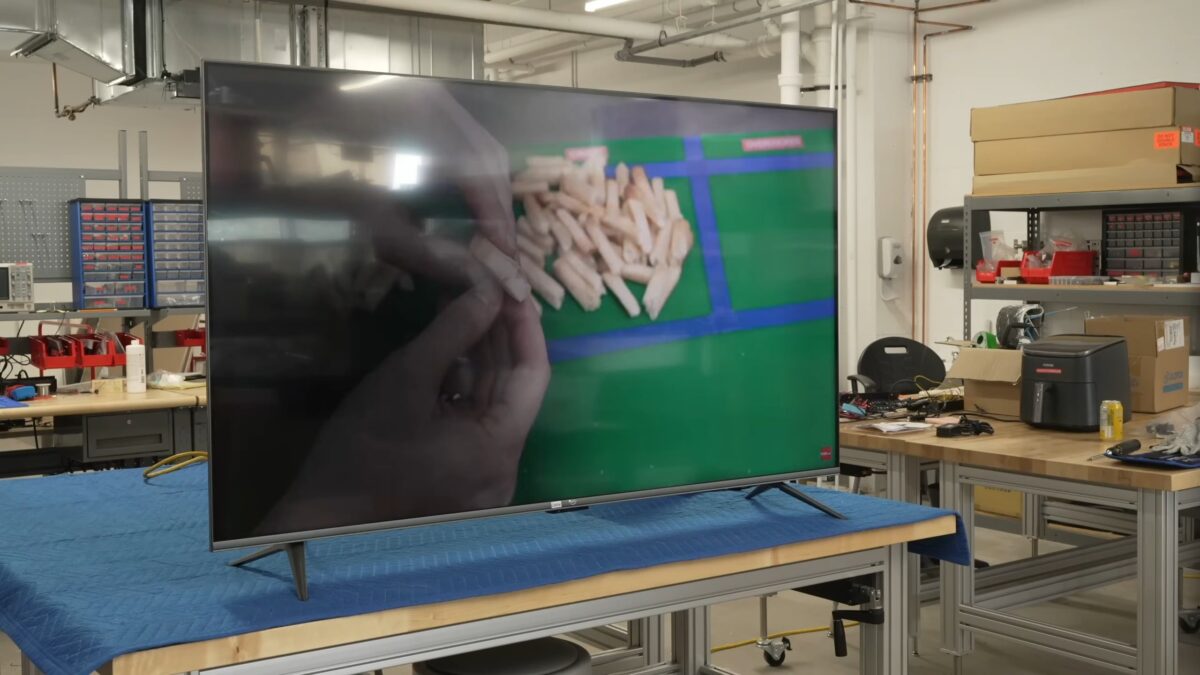

Rtings, a renowned independent testing laboratory, conducted an unprecedented endurance evaluation involving over 100 television units. The methodology pushed these displays far beyond typical household usage patterns, operating some units up to 20 hours daily. This extreme approach simulated approximately 10 years of normal viewing within a compressed timeframe. The objective wasn’t simply measuring gradual image degradation, but identifying which fundamental components would fail first under sustained stress.

The testing environment maintained consistent conditions across all units, eliminating variables that might skew results. Each display ran identical content patterns designed to stress both static and dynamic elements. Engineers monitored multiple parameters including luminosity, color accuracy, uniformity, and structural integrity. The sheer scale of this investigation provides unprecedented insight into real-world durability patterns that shorter evaluations miss entirely. What emerged wasn’t just incremental data, but a complete reassessment of which technology actually survives longer.

Interestingly, the protective mechanisms built into OLED displays to combat burn-in actually contribute to their superior mechanical reliability. Manufacturers implemented pixel-shifting algorithms, automated refresh cycles, and intelligent brightness management systems. These features, originally designed to prevent image retention, inadvertently create a more stable operational environment that reduces thermal stress on internal components.

Why LCD screens experience critical thermal breakdowns

The fundamental architecture of LCD technology creates an inherent vulnerability rarely discussed in consumer marketing materials. Unlike OLED panels where individual pixels generate light independently, LCD displays require continuous backlighting from arrays of LEDs positioned behind or around the screen perimeter. The liquid crystal layer must physically block this constant illumination to create dark areas, and this blocking process generates substantial heat energy that accumulates over time.

TechnologyUseful in summer, this button should never be switched on during the coldest months of the yearEdge-lit configurations, commonly used in slim television designs, concentrate LED arrays along the screen borders. This arrangement creates thermal hotspots where heat dissipation becomes problematic. The testing revealed that plastic reflector components within these assemblies literally melt or warp under prolonged thermal exposure. These deformations manifest as permanent dark patches, gray zones, or complete uniformity failures across sections of the display. Just as you would say goodbye to old screen protectors for better device protection, it’s time to reconsider outdated assumptions about display durability.

| Failure type | LCD frequency | OLED frequency | Reversibility |

|---|---|---|---|

| Complete LED array failure | High | N/A | Irreversible |

| Thermal component damage | High | Low | Irreversible |

| Gradual brightness reduction | Moderate | Moderate | Irreversible |

| Image retention | Low | Moderate | Partially reversible |

Full-array local dimming systems and Mini-LED implementations multiply these potential failure points exponentially. Thousands of individual LED zones require complex circuit boards and driver components, each representing additional thermal stress points. The study documented numerous instances where entire LED rows ceased functioning, creating horizontal bands of darkness that render displays essentially unusable. These represent mechanical catastrophes rather than gradual degradation, requiring complete component replacement rather than simple adjustment.

Understanding organic panel degradation versus mechanical failure

OLED technology isn’t immune to deterioration, but its failure mode differs fundamentally from LCD breakdowns. The organic compounds in OLED pixels do gradually diminish in efficiency, particularly red sub-pixels which historically demonstrate shorter lifespans than blue or green elements. Extended exposure to maximum brightness accelerates this process, and static imagery can create visible retention patterns that persist even after content changes.

However, the crucial distinction lies in how these issues manifest and progress. OLED degradation occurs gradually and somewhat predictably across the entire panel surface. Brightness decreases uniformly, color accuracy shifts systematically, and any image retention develops slowly over thousands of hours of specific static content exposure. Manufacturers anticipated these characteristics and engineered sophisticated countermeasures :

- Automated pixel shifting that imperceptibly moves content to prevent static element retention

- Scheduled maintenance cycles that run during standby periods to recalibrate pixel output

- Intelligent brightness limiting algorithms that reduce peak luminosity on static elements without affecting dynamic content

- Voltage compensation systems that adjust power delivery to aging pixels to maintain uniform appearance

These protective systems effectively extend usable lifespan while preventing the sudden, catastrophic failures observed in LCD units. An OLED display might gradually lose 10-15% of its peak brightness over 5-7 years of normal use, but it continues functioning. Conversely, an LCD television with a failed LED array or melted reflector becomes immediately unusable, regardless of how many hours remain before other components would naturally degrade.

Making informed decisions based on actual usage patterns

This research doesn’t eliminate the need for thoughtful technology selection based on individual circumstances. The 18,000-hour study provides clarity about mechanical reliability, but application context remains essential for optimal choice. Mixed entertainment usage including films, gaming, and varied television programming clearly favors OLED technology. Not only does it deliver superior image quality with perfect blacks and infinite contrast, but the documented mechanical reliability exceeds previous assumptions.

Specific use cases still warrant LCD consideration despite thermal vulnerability findings. Professional environments displaying static content for extended periods, such as computer monitors with persistent interface elements or commercial displays showing constant signage, may benefit from LCD’s resistance to image retention. The technology won’t develop permanent shadows from static logos or interface elements, even though thermal failure remains a statistical possibility before such retention would occur on OLED alternatives.

TechnologyMechanics don’t talk about it, the battery’s real enemy isn’t the coldThe key insight from this extensive testing program is that fear of burn-in should no longer dominate OLED purchasing decisions for typical residential viewing patterns. Statistical evidence suggests LCD backlight failures and thermal breakdowns occur more frequently than problematic OLED image retention under normal mixed-content usage. The longstanding perception that LCD represents the conservative, reliable choice no longer aligns with empirical durability data collected under rigorous testing conditions.